You own and manage your textiles

You need to know where textiles are, how they’re used, and when they should be replaced. Washd gives you clear visibility into textile lifecycles, loss, and usage, without manual tracking.

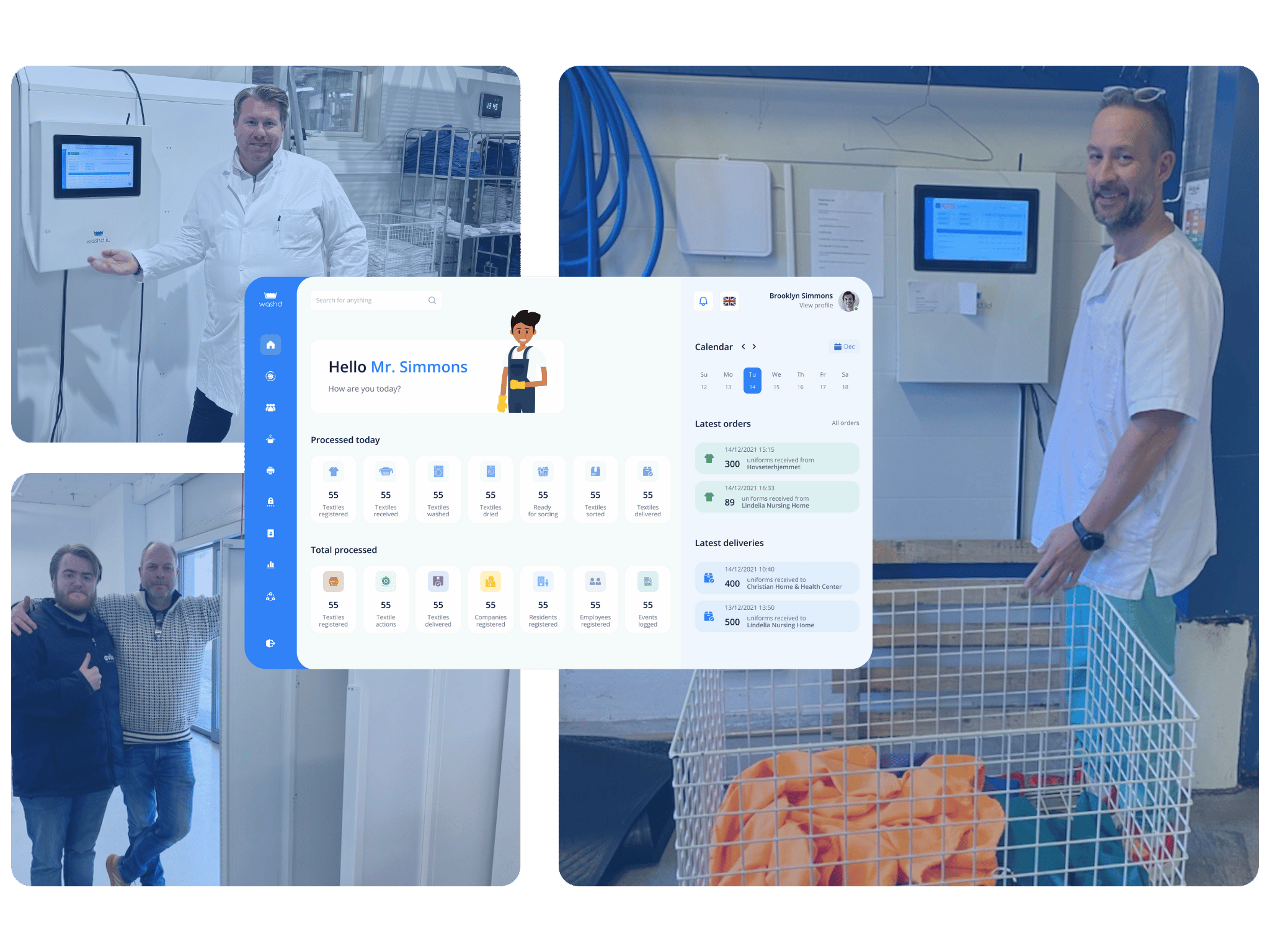

Trusted by 40+ laundries across Norway

In daily use across industrial laundry operations of different sizes.

Washd brings structure to the parts of laundry work that need visibility, coordination, and long-term reliability.

It connects textile tracking, guided workflows, and maintenance into one RFID-based software platform designed for industrial laundries.

Full visibility of textiles and operations.

Track where items are, spot discrepancies early, and base reporting and billing on real usage data.

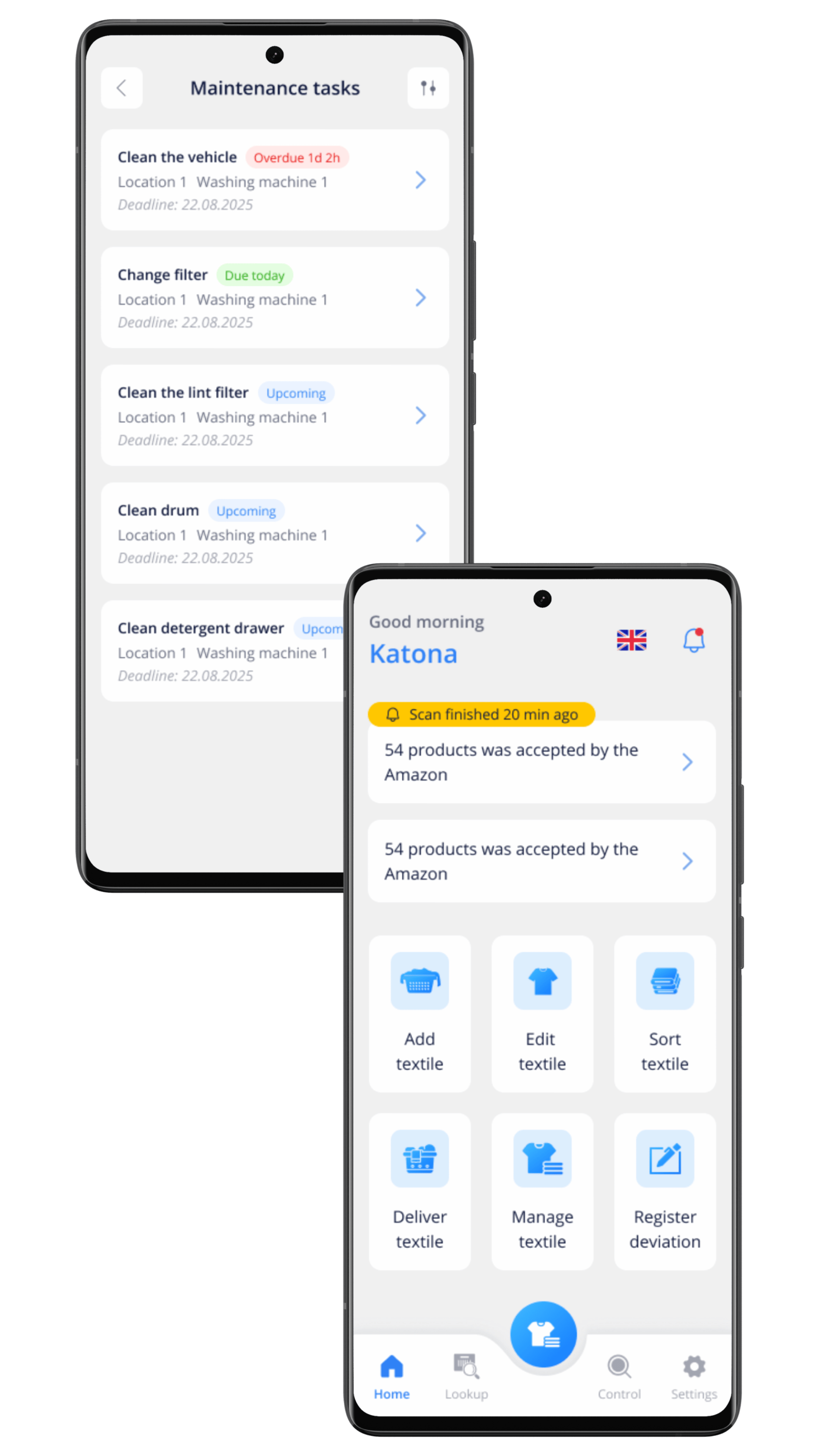

Guided sorting for mixed and high-volume laundry.

Clear screen or light guidance helps teams sort correctly, reduce errors, and work faster with less training.

Maintenance that keeps operations reliable.

Surface issues early, plan maintenance proactively, and avoid downtime that disrupts daily work.

Washd has completed over 25 million tasks in total.

Every week, over 120,000 new tasks are completed in Washd.

Over 330 employees use Washd daily.

Our customer support's average response time is just 8 seconds.

Key Benefits for Laundries

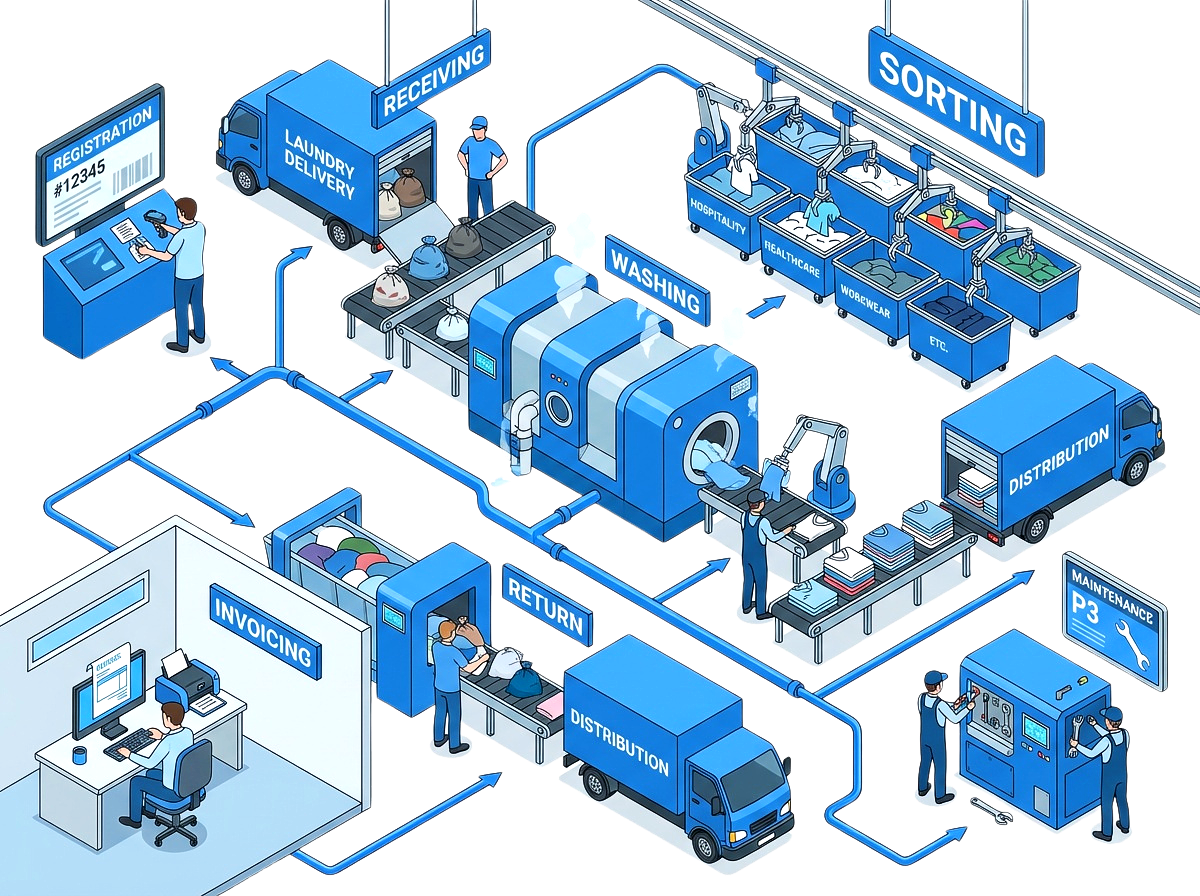

How Washd Supports Your Entire Laundry

The Hardware Behind Washd

You need to know where textiles are, how they’re used, and when they should be replaced. Washd gives you clear visibility into textile lifecycles, loss, and usage, without manual tracking.

You handle garments with usage limits or compliance requirements, such as firefighter gear or safety-critical workwear. Washd tracks usage, lifecycles, and documentation so requirements are met consistently.

You wash personal garments for care facilities or managed residential environments and need accurate separation, fewer errors, and predictable day-to-day routines.

For industrial laundries and professional dry-cleaning operations, reliable equipment and planned maintenance are critical. Washd helps surface issues early and support stable operations.