Washd Sorting

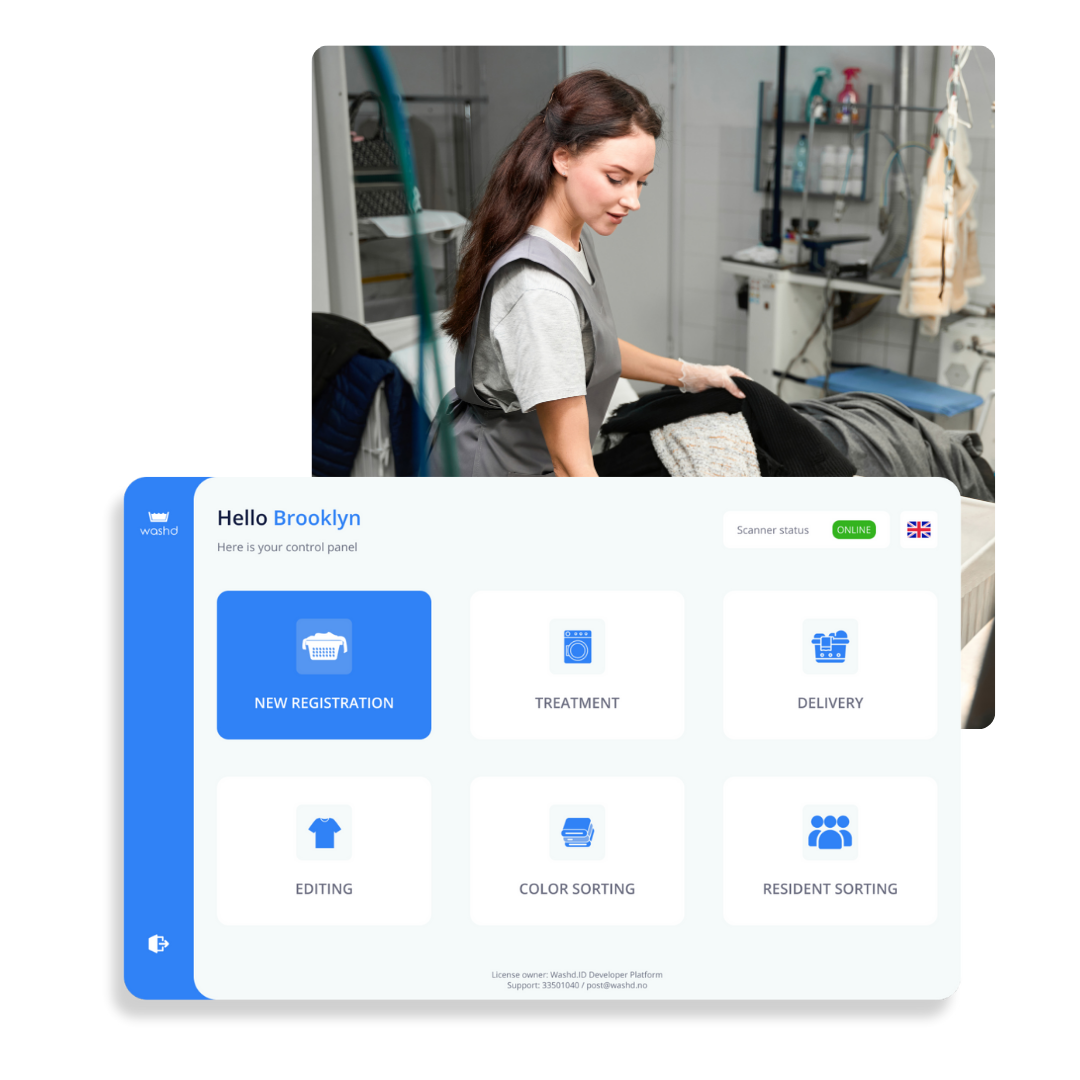

RFID Sorting Software for Industrial Laundries

The smartest sorting solution on the market for laundries.

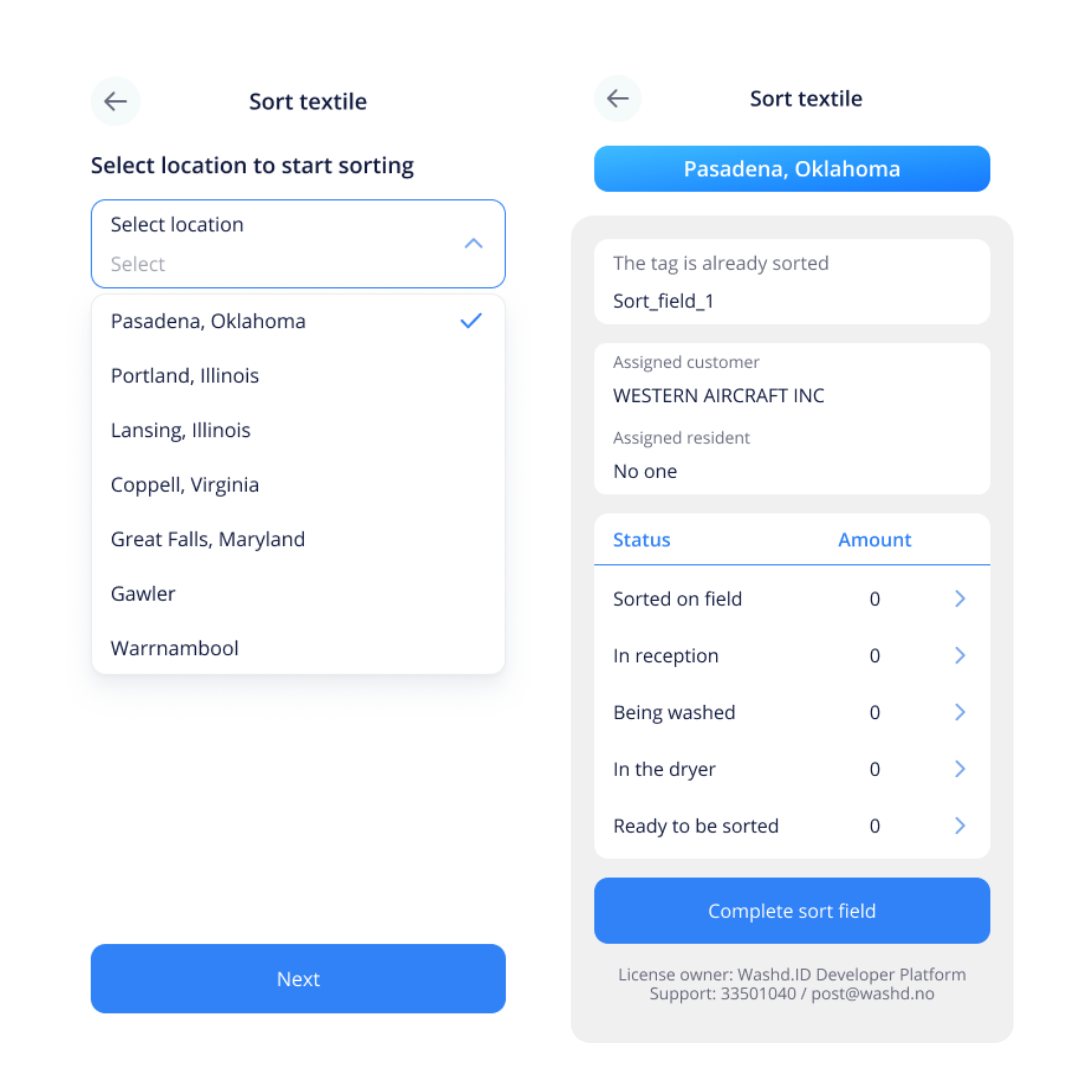

Sorting laundry for elderly homes and institutions is time-consuming, repetitive, and prone to errors (especially when multiple residents’ clothing is washed together).

Washd Sorting is an RFID-based laundry automation solution that guides staff through the sorting process with light or screen indicators. It ensures fast, accurate sorting of mixed textile loads, helping industrial laundries return clean items to the correct resident, unit, or department - without confusion or delay.

Two Smart Ways to Sort Laundry with Washd

Washd Sorting is available in two advanced configurations - both built to improve sorting accuracy, reduce strain on staff, and streamline mixed textile load processing.

Screen-Guided Laundry Sorting

Operators follow clear, on-screen instructions that show where and how to place each item. This setup functions as an intuitive RFID sorting table, ideal for laundries looking for simple, effective laundry sorting software with minimal setup.

Light-Guided Reaction-Based Sorting

In this advanced setup, smart shelf-edge lights guide the operator to the correct textile location.

✓ When an item is scanned, a green light appears above the shelf where it should be placed.

✓ If the textile is placed correctly, the green light turns off.

✓ If it's placed incorrectly, the light turns red, providing immediate, intuitive feedback.

This RFID-based laundry sorting system helps operators sort faster and more accurately, significantly reducing errors and rework.

How It Works

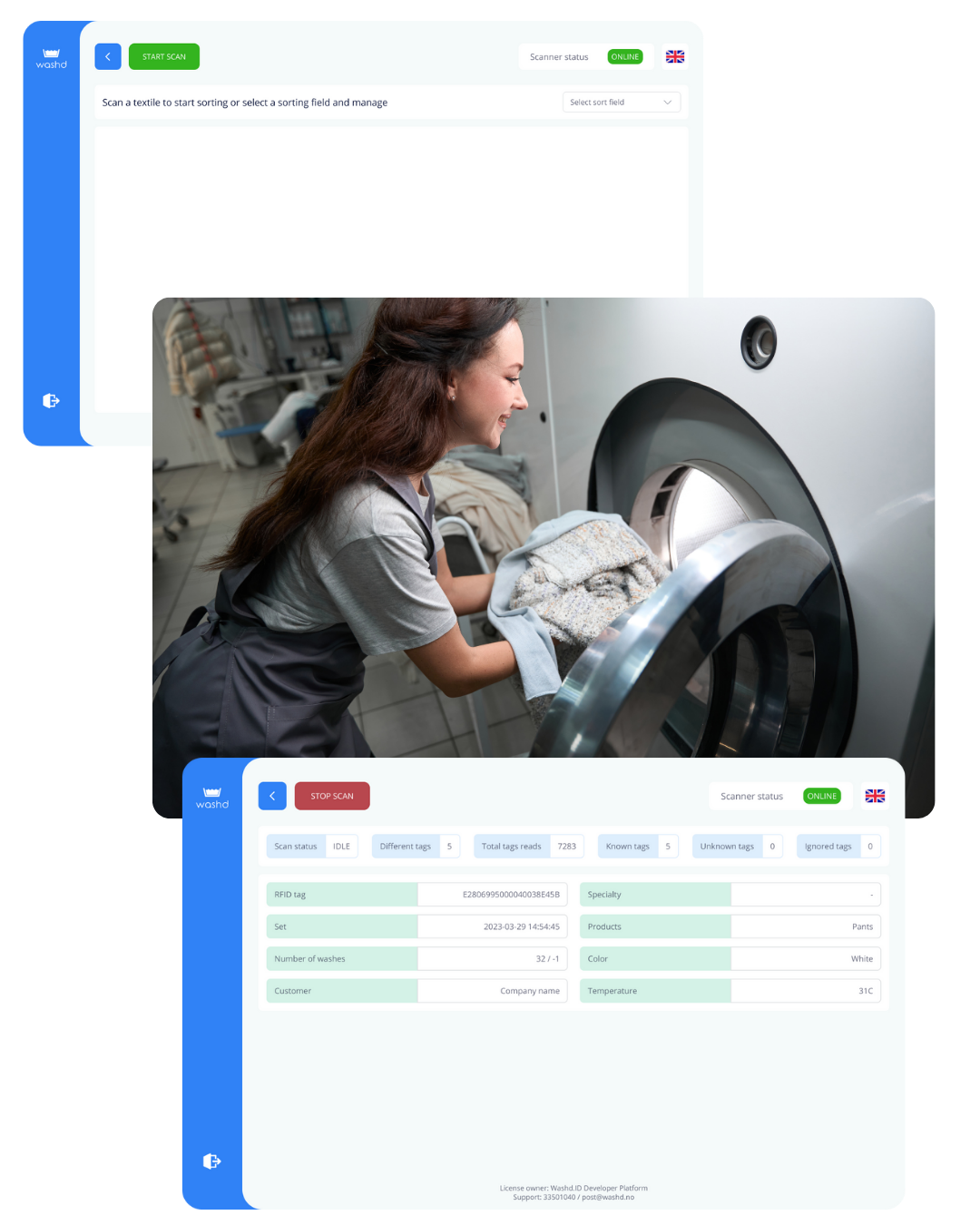

1. Scan Each Textile

Each item is tagged with an RFID chip. As items enter the sorting area, they're scanned using an RFID sorting table or reader. The system instantly identifies the item, its owner, and its destination.

2. Get Guided Placement

Based on sorting rules, the system tells the operator where to place the item. This can be shown via:

- On-screen instructions (e.g. “Shelf 3 – Top Right”)

- Or smart shelf-edge lights - a green light appears above the correct compartment.

3. Confirm or Correct

If the item is placed correctly, the green light turns off.

If placed incorrectly, the light turns red and a sound alert notifies the operator, reducing errors in real time.

4. Repeat & Track Progress

Operators continue scanning and sorting with live system feedback. Supervisors can monitor progress with real-time sorting visibility and view reporting data per client, resident, or load.

Key Benefits of Washd Sorting

Learn More About RFID & Laundry Tech

How RFID Technology is Shaping the Future of Laundry Management

5 Tech Trends Shaping the Future of the Laundry Industry

Revolutionizing Laundry Management: Why Washd is the Future of Textile Care

Developed in Norway -

Made for laundries