Washd PREVENT

Preventive Maintenance Software for Industrial Laundries

Stop reacting to breakdowns, and start preventing them.

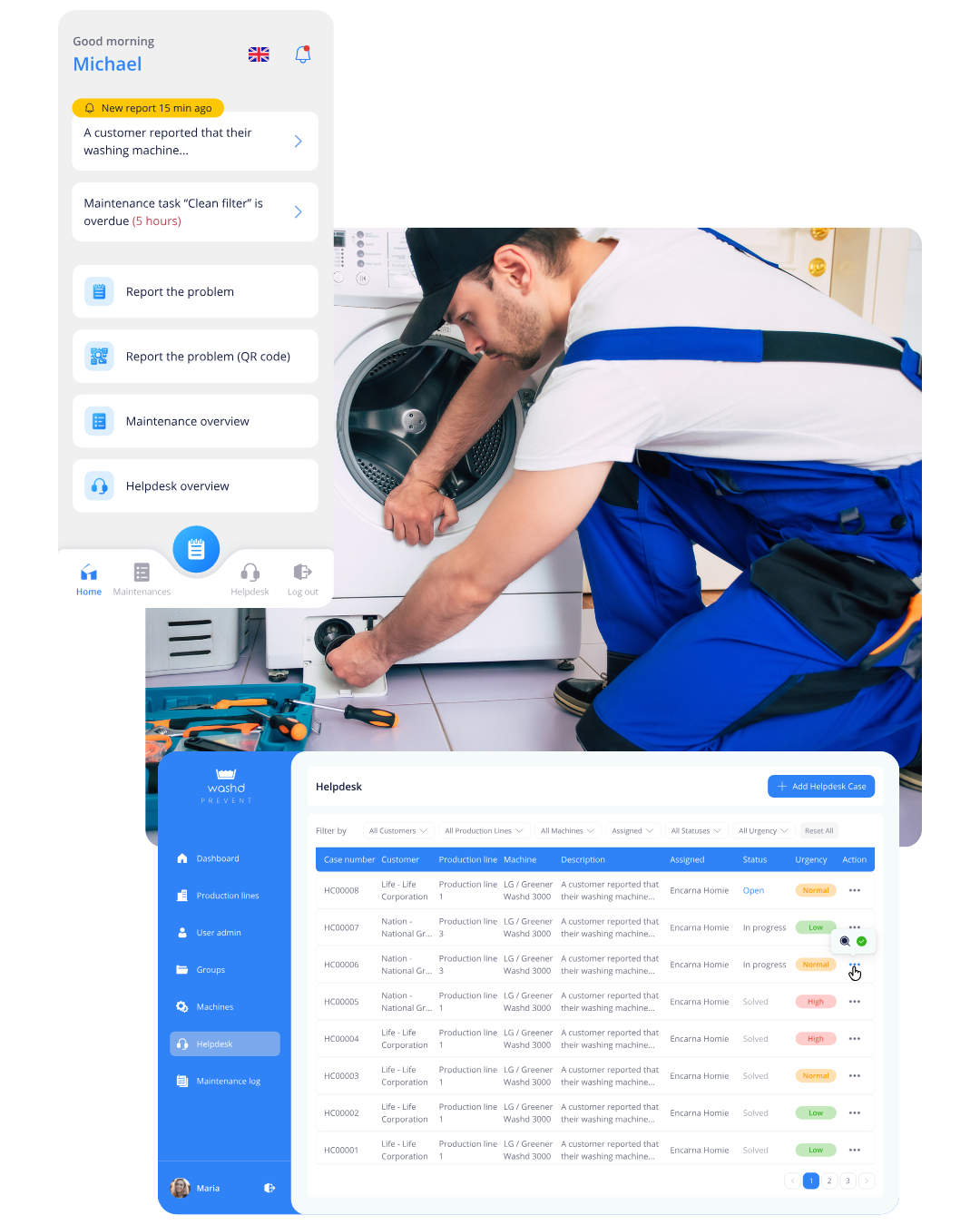

Washd Prevent is a mobile-first preventive maintenance system designed specifically for industrial laundry operations. From daily checks to full equipment servicing, it helps you schedule, assign, and track maintenance tasks across one or multiple facilities.

Stay ahead of equipment failures, reduce downtime, and keep your laundry running at full efficiency.

Key features

✓ Preventive Maintenance Scheduling: Plan recurring tasks across all your laundry equipment. Access built-in service schedules from equipment suppliers (daily, weekly, annual), so nothing is missed.

✓ Mobile Work Order Management: Assign, complete, and track tasks from any mobile device. Staff can log time, upload photos, and manage their workload on the go, making mobile maintenance tracking simple and efficient.

✓ Time Tracking & Task History: Track how much time is spent per task, monitor service history by machine, and generate reports to improve workflow visibility and efficiency.

✓ Scalable & Supplier-Ready: Whether you manage one laundry or a national chain, Washd Prevent supports your scale. You can also assign tasks to external suppliers and monitor work completed, time spent, and response time.

✓ Visual & Test-Based Documentation: Attach images to any task and log pH or bacteria test results directly in the system - supporting internal QA processes and consistent equipment health checks.

✓ Multi-Equipment Support: From coffee machines to ventilation systems, Washd Prevent supports maintenance tracking for your entire facility - not just your core laundry equipment.

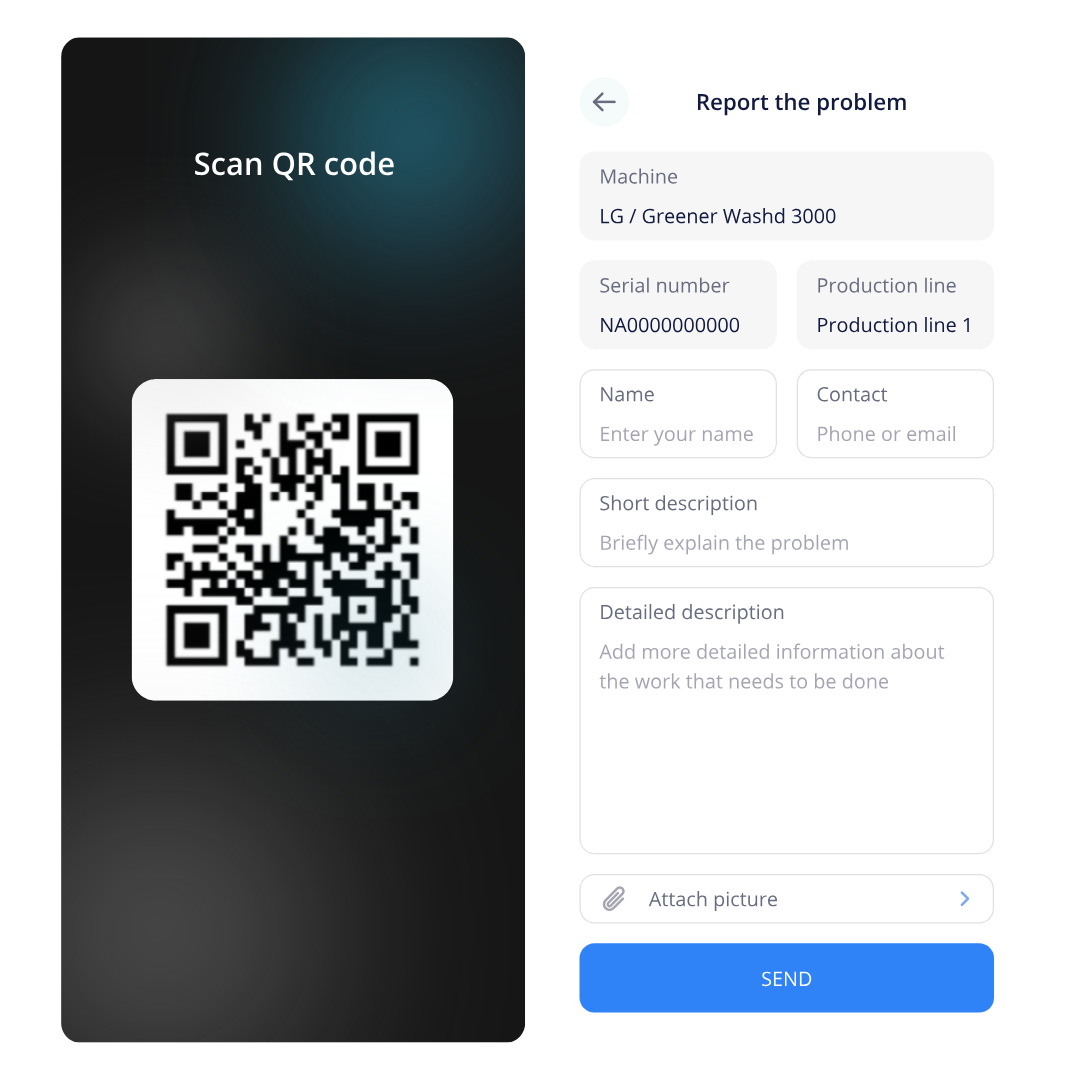

✓ QR Code Error Reporting: Place QR codes on machines so staff can instantly report issues with a photo and short message - no training required.

✓ Reminders & Escalations: Stay ahead of every task with calendar views and automated reminders. Easily escalate service requests to suppliers when internal handling isn’t enough.

How It Works

1. Schedule Preventive Tasks

Use built-in supplier schedules or create your own. Tasks can be set by machine, team, or frequency - including annual routines like inspections, fire drills, and custom laundry equipment checks.

2. Assign & Complete from Mobile

Team members receive tasks on mobile, mark them complete, add notes, and log time - all while working on the laundry floor.

3. Monitor Progress in Real Time

View dashboards with live status updates, maintenance progress, time spent, and any overdue tasks - all in one control panel.

4. Report Issues or Escalate

Scan QR codes on machines to report issues instantly with a photo and message. If internal handling isn’t enough, escalate tasks to external suppliers. Log quality checks like pH and bacterial tests directly into the system for future reference.

Key Benefits of Washd Prevent

Learn More About Laundry Maintenance Tech

Meet Maia: The AI-Powered Assistant for Hassle-Free Laundry Maintenance

NRV & NVK 2025 Recap: Washd Prevent, Maia AI, and the Future of Laundry Operations

Simplifying Laundry Maintenance: How Washd Prevent Transforms Operations

Developed in Norway -

Made for laundries