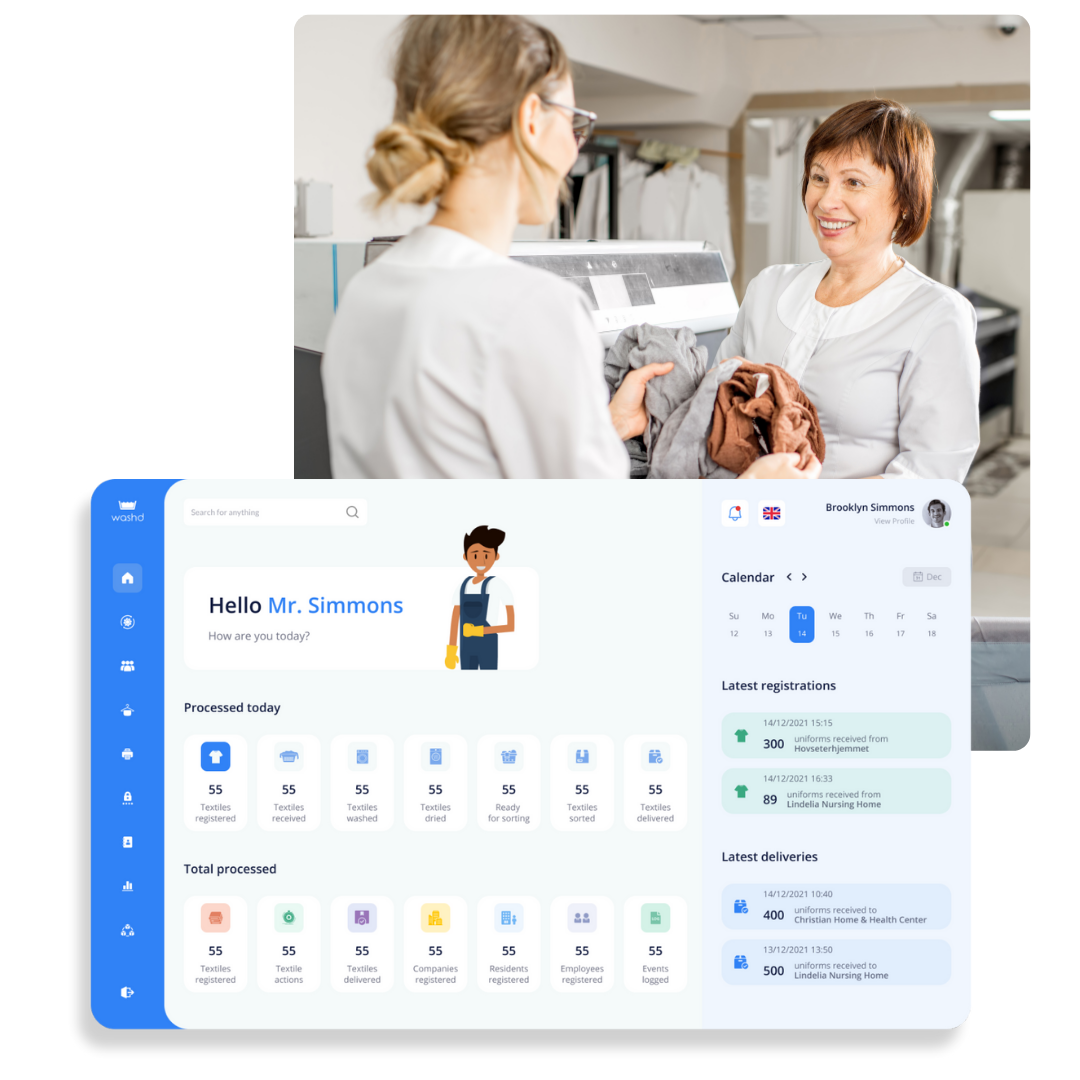

Washd Control

RFID Textile Tracking System for Industrial Laundries

What if you could track every textile in your laundry, at every stage, without manual checks?

With Washd Control, you can.

This advanced RFID laundry tracking system gives you real-time inventory visibility and control, from the moment an item enters your facility to when it’s returned.

Whether you're managing hospital linens, hotel towels, or fire-resistant uniforms, Washd Control helps you monitor every item in real time. It's especially valuable for textiles with strict usage limits, supporting compliance, loss prevention, and textile lifecycle management, all in one system.

Key features

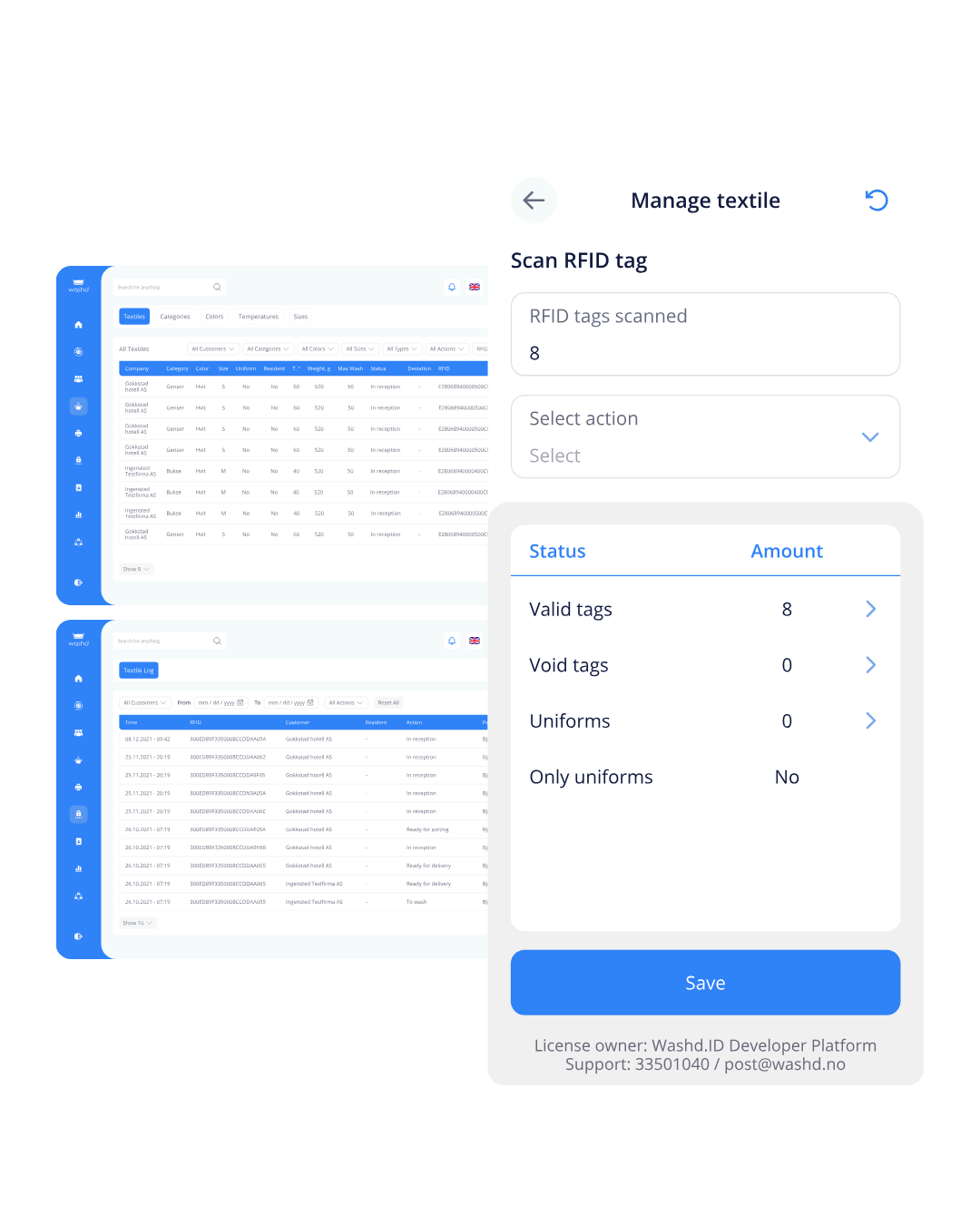

✓ RFID Textile Tracking System: Track each textile from the moment it leaves your facility until it returns. Washd Control uses RFID technology to log every use, making it easy to monitor wear, schedule replacements, and maintain compliance.

✓ Laundry Inventory Control System: See exactly what’s in stock, what’s in use, and what’s missing. Always know where your textiles are, and where they should be.

✓ Automated Invoicing for Lost Textiles: Get alerts when items don’t come back. Washd Control flags missing textiles and makes billing for losses fast and simple.

✓ Textile Lifecycle Management: Keep track of how many times each item has been used or washed. Receive automatic alerts when items hit usage limits or need to be retired.

✓ Accounting System Integration: Connect directly to systems like Visma.NET and PowerOffice Go. Create invoices automatically and save time on admin.

✓ Reports & Compliance Insights: Generate reports on textile usage, shrinkage, and customer retention times. Ensure you're audit-ready and aligned with hygiene and safety standards.

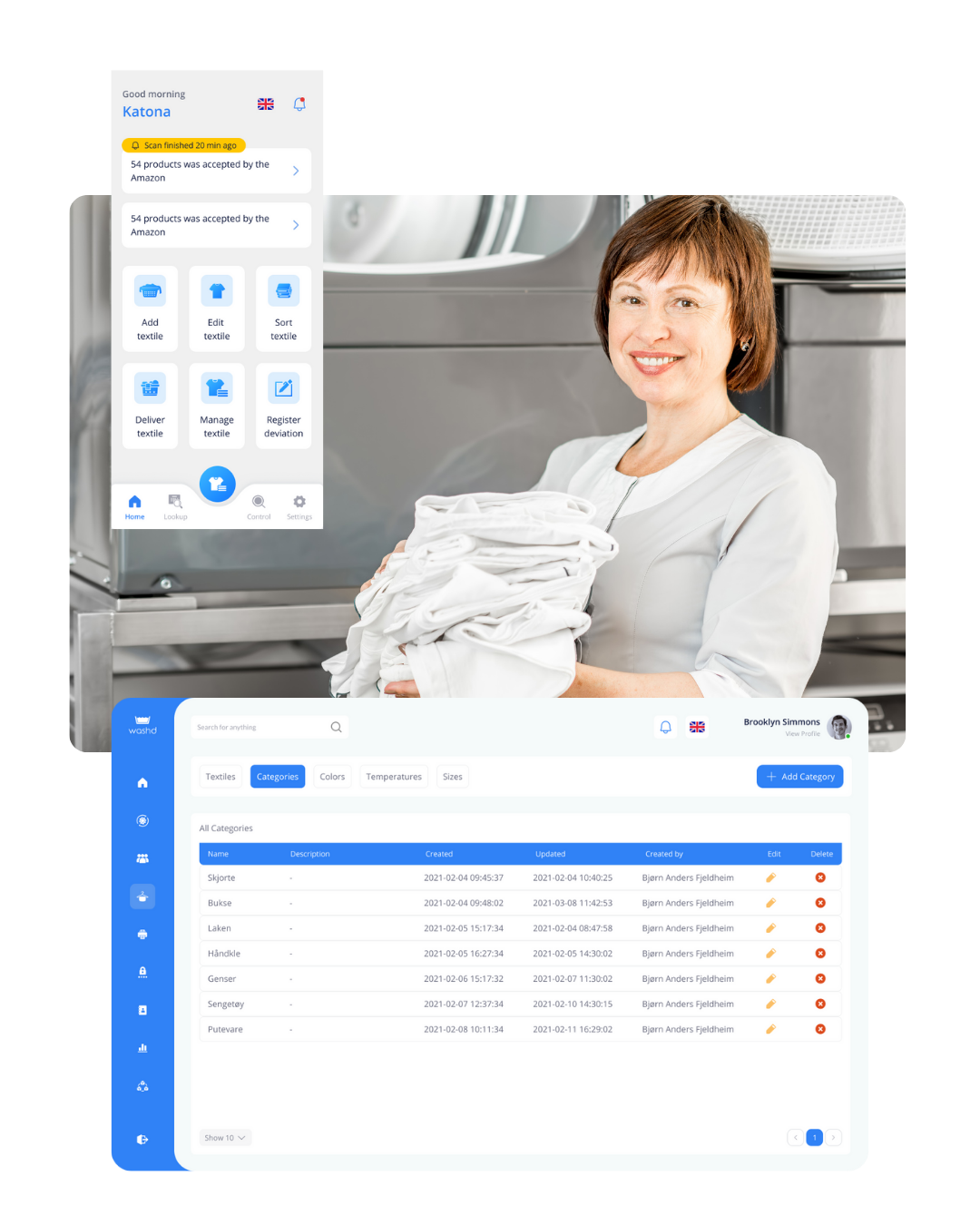

✓ User-Friendly Interface: Designed to be intuitive and accessible for all types of users, regardless of technical expertise.

How It Works

1. Tag Every Textile with RFID

Each item is fitted with a durable RFID tag, built to survive industrial washing, drying, and handling. Tags are linked to product details, customer accounts, and textile lifecycle rules.

2. Scan Automatically at Entry & Exit

Textiles are scanned at key points using fixed or handheld RFID readers. The system logs each scan instantly - tracking movement, timestamps, and item status without manual data entry.

3. Monitor Textile Inventory in Real Time

Washd Control updates your textile inventory as items move through the system. You’ll see which items are in use, where they are, how long they’ve been out, and whether anything is missing or overdue.

4. Analyze & Act

Use built-in reports to track textile lifespan, customer handling patterns, and loss trends. Set up automatic alerts for non-returns or overused items, and connect to your accounting system for seamless invoicing.

Key Benefits of Washd Control

Learn More About RFID & Laundry Tech

Taking Laundry Innovation Further: Smarter Scanning with the New L2000 automatic scanner

How RFID Technology is Shaping the Future of Laundry Management

Installing the Washd Scanning Cage at Ålesund Vekst: A Step Toward Smarter Laundry Management

Developed in Norway -

Made for laundries